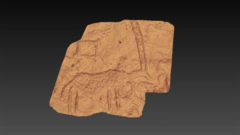

Chris Beard and Sandra Olsen perform 3-D laser scanning of a petroglyph at Jubbah.

A 3-D laser scanner is a device that analyzes an object to collect precise data of its shape and appearance. The collected data can then be used to construct digital 3-D models on the computer screen or to print out actual physical replicas of the object in resin or plaster (known as a rapid prototype). Because this method is totally non-destructive, 3-D digital laser imaging has already been applied to several cultural heritage projects involving either historical sites or artifacts, for both documentation and analytical purposes. The combination of 3-D scanning and rapid prototyping technologies allows the replication of valuable cultural heritage objects in epoxy resin or other material for which traditional molding and casting techniques would be too risky or difficult.

The 3-D laser scanner employs the light emitted from a laser to probe the subject. The primary component of the scanner is a time-of-flight laser range-finder that determines the distance between the instrument and a spot on the surface of an object. It does this by timing the round-trip time of a pulse of light that is emitted from the instrument and reflected back to its detector by the object. Since the speed of light is known, the round-trip time determines the travel distance of the light, which is twice the distance between the scanner and the surface.

Because the laser range-finder only detects the distance of one point in its direction of view at a time, the scanner must scan its entire field of view, one point at a time, by constantly changing the range-finder’s direction of view. The view direction of the laser range-finder is usually changed via a system of rotating mirrors. Typical time-of-flight 3-D laser scanners can measure the distance of 10,000 to 100,000 points every second. The accumulated data allow a highly accurate 3-D model to be produced in a computer-generated file.

We produced 3-D images of sections of petroglyphs in order to record the precise size of individual figures, measure the depth of incised or chiseled lines, determine the shapes of the profile of these manufactured grooves, and identify the sequence in which overlapping figures were created. Like RTI’s and night photography, 3-D laser scanned images show considerably more details regarding surface relief than does traditional photography. Further, 3-D laser scanning enables precise replicas (rapid prototypes) in resin of certain images for display in museums and for hands-on experiences for educational purposes.